Manufacturing Process of aluminium profile in East Asia Aluminum

Nowadays, aluminum profiles are widely used not only in construction, and industry but also in home design. Therefore, aluminum profiles become indispensable materials in life. However, it is very difficult to choose standard quality aluminum profiles. So what is the process of producing aluminum profiles to have high-quality products, let's find out right away!

Manafacturing process of aluminum profile

What is Industrial Aluminum Profile?

Aluminum profiles are aluminum bars that have undergone a manufacturing process to optimize the properties of aluminum. Using silver-white aluminum material, soft and easy to process, combined with additives such as Si, Mg... After the extrusion process, it will create aluminum profiles with many different profiles.

Industrial aluminum profile is a type of aluminum that has been metalized to optimize its properties of aluminum. Finished products will be aluminum bars with corrosion resistance, high strength but lightweight, and easy mechanical processing. The ability to combine different types of glass and lock has enabled aluminum profiles to create a wide range of options for customers, becoming a highly popular aluminum.

Aluminum profiles have strength, high corrosion resistance, lightweight, and easy mechanical processing. They are easily assembled with different types of glasses and locks to create a variety of products when produced.

Readmore: What is industrial aluminum ? Advantages and applications of industrial aluminum.

The standard manufacturing process of industrial aluminum profiles

To produce high quality through the steps:

- of strict material quality control

- Implement standard production processes

- Check product quality standards

The new aluminum profiles are packaged and put on the market for consumption. The production process is detailed through the following steps:

Step 1: Importing raw materials, also known as aluminum ingots

The initial materials imported will be in the form of raw ingots, called aluminum ingots. The aluminum billet is an alloy of aluminum and other elements such as Silicon, magnesium, manganese, copper, tin…

Step 2: Check the quality of aluminum before smelting Aluminum

Alloys are commonly used in the production of aluminum profiles. are aluminum alloy 6063 and 6061. These materials are mainly imported from Malaysia, Thailand, Australia...

The imported aluminum billet will be tested for Bo, Ti, and homogenized by a defect testing machine. To classify aluminum billet pass and fail to provide for the production of high-quality aluminum bars.

Step 3: Design drawings of aluminum

Our aluminum profiles are designed with its product line with a team of professional engineers. We always research, strive and constantly innovate to produce high-class aluminum door design products to meet all the needs of consumers. Drawings of aluminum bars must meet the standards of quality, materials, and safety, and ensure the nature of use.

Step 4: Casting

Industrial aluminum profile die casting must be based on standard drawing criteria. The aluminum die ensures a safe casting process. The heat resistance of the mold is given top priority. It must also be easy and convenient to take aluminum bars from the die.

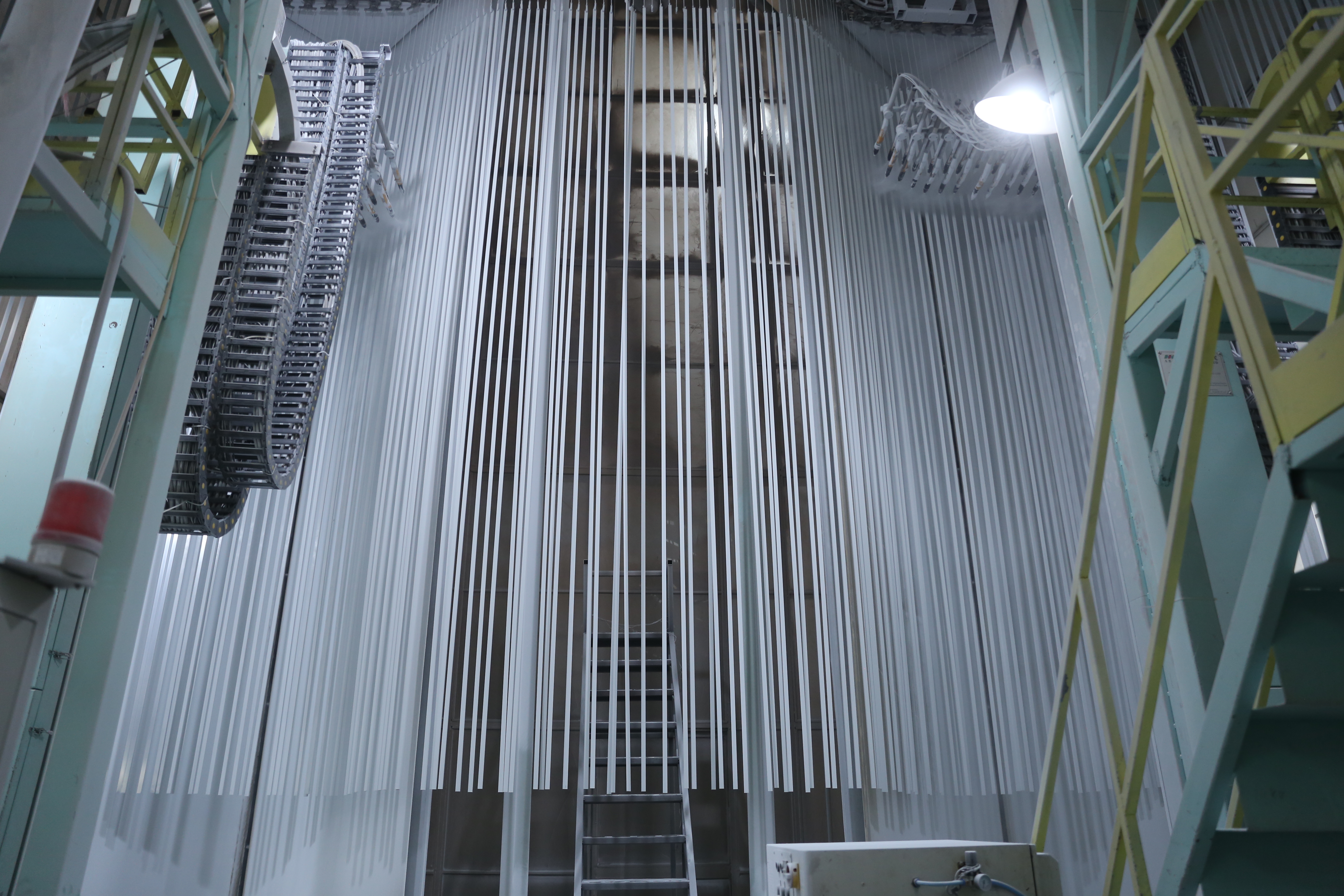

Step 5: Extrusion of aluminum

Billet aluminum after inspection will be put into a hot cutting machine. Using the heat of about 430 - 450 degrees to cut into pieces of an aluminum billet of suitable length for production purposes.

Before performing the extrusion process, it is necessary to check the mold to ensure the correct model. Depending on the needs, the purpose of using the mold will have different sizes and designs. Heat resistance is an essential and top priority in the pressing process. At the same time, taking aluminum from the die after pressing must be done easily and conveniently.

Proceed to cast pure aluminum billet at about 600 degrees Celsius. The melted alloy product is poured into the casting mold to shape the aluminum shape. The products after casting will be homogenous to create uniformity of products, and stability of the structure.

Step 6: Check the composition after extrusion

The aluminum billet after casting will conduct an analysis of the metal composition, and if satisfactory, will be cut into small pieces suitable for each type of aluminum bar and then heated and transferred to the press to produce aluminum bars shaped according to the designed mold.

Step 7: Processing the hardness of aluminum profiles

Depending on the requirements of the customer, aluminum is decided on whether to be put into an autoclave to increase hardness or not. It also depends on different types of aluminum alloy to decide the appropriate hardness.

After the hardness has been tested to meet the standards, the aluminum will be processed for processing or plating, painting, and sandblasting according to customer requirements.

Step 8: Surface treatment

Aluminum profiles that meet the standards in size, composition, and hardness will be surface treated.

- FABRICATION PROCESSING: Depending on the needs of the customer, aluminum will be processed through stages such as punching, drilling, welding, sandblasting, etc.

- POWDER COATED: The process is performed in an automatically controlled spray booth. To create a layer of electrostatic paint that meets the requirements: smooth, not peeling, the paint color is according to the original design

- Anodizing: Aluminum anodizing method according to advanced technology, surface ED color coating, especially to color the product, makes the product a high gloss, anti-corrosion and does not fade over time.

Step 9: Checking

Product quality is the deciding factor in whether the industrial aluminum profile manufacturing process meets the standards or not. The product will undergo a test for quality, durability, and color to conclude. At the same time, remove problematic products such as color deviation, damage, wrong proportions ...

Aluminum profiles must ensure 3 basic criteria: color, quality, and durability. Discarded products often have problems: color deviation, damage, and out-of-proportion molding. After completing the inspection and evaluation process, the products will be put into the factory warehouse and served for the next product distribution process.

Upon completion of the inspection, the qualified products will be certified and transferred to the warehouse for packaging, in stock, delivery and distribution to the market.

The production process of standard industrial aluminum profiles will be more complicated and requires many small steps, so if you need to use industrial aluminum profiles, definitely choose long-term brands years on the market to be 100% confident about product quality and usability!

For specific advice, please contact Hotline 0220 359 2956 or email sales@nhomdonga.vn

EAST ASIA ALUMINUM COMPANY LIMITED

Address: Tan Dan Industrial Cluster, Chi Linh City, Hai Duong Province

Phone: 0084-220.359.2956

Email: sales@nhomdonga.vn